- होम पेज

- कंपनी प्रोफाइल

-

हमारे उत्पाद

- उन्नत नैनो सामग्री

- मोलिब्डेनम डाइसल्फ़ाइड पाउडर, MoS2

- कार्बन नैनोफाइबर (CNF)

- ब्लैक फॉस्फोरस क्रिस्टल

- ब्लैक फॉस्फोरस पाउडर

- मोलिब्डेनम डाइसल्फ़ाइड (MOS2) क्वांटम डॉट्स

- मोनोलेयर मोलिब्डेनम डाइसल्फ़ाइड

- नैनो साइज मोनोलेयर टंगस्टन डाइसल्फ़ाइड

- टंगस्टन डाइसल्फ़ाइड

- मोनोलेयर टंगस्टन डाइसल्फ़ाइड

- ग्राफिटिक कार्बन नाइट्राइड (G-C3n4) पाउडर

- कॉपर फ़ॉइल पर हेक्सागोनल बोरॉन नाइट्राइड (H-BN)

- Si/SiO2 पर हेक्सागोनल बोरॉन नाइट्राइड (H-BN)

- टंगस्टन डाइसल्फ़ाइड (WS2)

- नैनो साइज मोनोलेयर टंगस्टन डाइसल्फ़ाइड, WS2

- मोनोलेयर टंगस्टन डाइसल्फ़ाइड पाउडर, WS2

- मोनोलेयर टंगस्टन डाइसल्फ़ाइड (WS2) क्वांटम डॉट्स

- मिश्र

- आयरन निकेल अलॉय नैनोपाउडर

- कॉपर बेरिलियम मिश्र धातु नैनोपाउडर

- कॉपर जिंक मिश्र धातु नैनोपार्टिकल्स

- एल्यूमीनियम मैग्नीशियम मिश्र धातु नैनोपाउडर

- कॉपर टिन अलॉय नैनोपाउडर

- इनकोनेल 625 निकेल अलॉय नैनोपाउडर

- कोबाल्ट आयरन मिश्र धातु पाउडर

- लैंथेनम आयरन पैलेडियम अलॉय नैनोपाउडर

- मैग्नीशियम कैल्शियम मिश्र धातु पाउडर

- एल्यूमीनियम मिश्र धातु पाउडर

- एल्यूमीनियम कास्टिंग मिश्र धातु पाउडर

- तांबा निकल मिश्र धातु नैनोपाउडर

- कॉपर सिल्वर अलॉय नैनोपाउडर

- टिन कॉपर मिश्र धातु पाउडर/नैनोपाउडर

- देवरदा मिश्र धातु पाउडर

- हेफ़नियम कार्बाइड पाउडर

- ज़िरकोनिया टफनेड एलुमिना अलॉय पाउडर

- सिल्वर कॉपर अलॉय नैनोपार्टिकल्स

- ज़िरकोनियम पैलेडियम मिश्र धातु पाउडर

- निकेल जिंक आयरन ऑक्साइड मिश्र धातु पाउडर

- टिन कॉपर मिश्र धातु पाउडर

- टिन लीड अलॉय नैनोपार्टिकल्स

- कॉपर क्रोमियम मिश्र धातु नैनोपाउडर

- आयरन निकेल कोबाल्ट अलॉय नैनोपाउडर

- एल्युमिनियम एलॉय नैनोपाउडर

- टाइटेनियम एल्यूमीनियम वैनेडियम मिश्र धातु पाउडर

- लैंथेनम निकेल अलॉय नैनोपाउडर

- कोबाल्ट क्रोमियम मोलिब्डेनम मिश्र धातु पाउडर

- मैंगनीज जिंक अलॉय नैनोपाउडर

- सिलिकॉन एल्यूमीनियम मिश्र धातु नैनोपाउडर

- आयरन पाइराइट अलॉय नैनोपाउडर

- आयरन सिलिकॉन अलॉय नैनोपाउडर

- नियोडिमियम आयरन बोरॉन नैनोपार्टिकल्स

- निकेल क्रोमियम कोबाल्ट अलॉय नैनोपाउडर

- एल्यूमीनियम मिश्र धातु पाउडर

- मोलिब्डेनम डिसिलिसाइड पाउडर

- लैंथेनम सेरियम ज़िरकोनेट पाउडर

- लान्थेनम हाफ़नियम ज़िरकोनेट पाउडर

- अनुप्रयोग उन्मुख सामग्री

- कृत्रिम जैविक समाधान

- कार्बन नैनोट्यूब और फुलरीन

- शॉर्ट लेंथ मल्टी वाल्ड कार्बन नैनोट्यूब (MWCNT)

- कार्यात्मक SWCNT-सिंगल वाल्ड कार्बन नैनोट्यूब

- शॉर्ट लेंथ सिंगल वाल्ड कार्बन नैनोट्यूब (SWCNT)

- फंक्शनल शॉर्ट MWCNT-मल्टी वाल्ड कार्बन नैनोट्यूब

- फंक्शनल शॉर्ट MWCNT-मल्टी वाल्ड कार्बन नैनोट्यूब

- मल्टी वाल्ड कार्बन नैनोट्यूब (MWCNT)

- SWCNT-सिंगल वाल्ड कार्बन नैनोट्यूब

- कार्बन नैनोट्यूब (मल्टी और सिंगल वाल्ड)

- कोर शैल नैनो और सूक्ष्म संरचनाएं

- Au TiO2 कोर शेल नैनोपार्टिकल्स

- गोल्ड कॉपर आयोडाइड कोर शेल नैनोपार्टिकल्स

- आयरन निकेल सिलिका कोर शेल नैनोपार्टिकल्स

- गोल्ड सिल्वर कोर शेल नैनोपार्टिकल्स

- आयरन ऑक्साइड सिलिका कोर शेल नैनोपार्टिकल्स

- जिंक सल्फर मैंगनीज सिलिका कोर शेल नैनोपार्टिकल्स

- निकेल सिलिका कोर शेल नैनोपार्टिकल्स

- गोल्ड सिलिकॉन ऑक्साइड कोर-शेल नैनोपार्टिकल्स

- सिल्वर सिलिका कोर शेल नैनोपार्टिकल्स

- ZnO SiO2 कोर शेल नैनोपार्टिकल्स

- कॉपर सिलिका कोर/शेल नैनोपार्टिकल्स

- सिलिका कोर शेल नैनोपार्टिकल्स

- एजीआई सिलिका कोर शेल नैनोपार्टिकल्स

- एल्यूमीनियम सिलिकॉन ऑक्साइड कोर शेल नैनोपार्टिकल्स

- सिल्वर सिलिका कोर शेल नैनोपार्टिकल्स

- कोबाल्ट सिलिका कोर शेल नैनोपार्टिकल्स

- गोल्ड कैडमियम सेलेनियम कोर शेल नैनोपार्टिकल्स

- आयरन ऑक्साइड सिलिकॉन डाइऑक्साइड टाइटेनियम ऑक्साइड कोर शेल

- ब्लू ल्यूमिनेसेंट ग्राफीन क्वांटम डॉट्स

- गोल्ड कोबाल्ट कोर शेल नैनोपार्टिकल्स

- गोल्ड प्लेटिनम कोर शेल नैनोपार्टिकल्स

- कैडमियम सेलेनाइड कैडमियम सल्फर सिलिका कोर शेल एनपीएस

- आयरन ऑक्साइड सिलिका कोर शेल नैनोपार्टिकल्स

- आयरन निकेल सिलिका कोर शेल नैनोपार्टिकल्स

- गोल्ड प्लेटिनम कोर शेल नैनोपार्टिकल्स

- फैलाव नैनो और माइक्रो

- सिलिका फैलाव (SiO2, जलीय फैलाव, अनाकार; 5-35 एनएम)

- सिल्वर कोलाइडल फैलाव (एजी, कोलाइडल, शुद्धता: 99.99%, एपीएस: 20 एनएम)

- सिल्वर फैलाव नैनोपार्टिकल्स (एजी, कोलाइडल, शुद्धता: 99.9%, एपीएस: 150 एनएम)

- सेंट फैलाव (> 95%, व्यास: 1-2 मिमी, लंबाई: 5-10 मिमी)

- एमपीएस लिगैंड के साथ नाइओबियम पाउडर (शुद्धता: > 99.99%, एपीएस: 80-100 एनएम)

- पानी में कार्बन नैनोफाइबर फैलाव (लंबाई: 30 उम)

- ऑक्टाविनील पॉस (ऑक्टाविनाइलोक्टैसिलस क्विओक्सेन, शुद्धता: 99.99%)

- प्लेटिनम फैलाव (पीटी, शुद्धता: 99.99%, एपीएस: 1-10 एनएम)

- MWCNT फैलाव (ऑर्गेनिक सॉल्वेंट, व्यास: 20-30 एनएम, लंबाई: 5-15 um)

- कॉपर जिंक अलॉय नैनो फैलाव (Zn Cu, शुद्धता: 99.99%, APS: 50 nm)

- एल्यूमीनियम पाउडर फैलाव

- यिट्रियम डोप्ड जिंक ऑक्साइड फैलाव (Y/ZnO, टोल्यूनि, 99.9%, APS: 50 एनएम)

- कॉपर नैनोपार्टिकल्स इंक फैलाव

- बेरियम सल्फेट फैलाव (Baso4, 99%, 200-500 एनएम)

- कैल्शियम कार्बोनेट फैलाव (Caco3, शुद्धता: 99.99%, एपीएस: <80 एनएम)

- बिस्मथ ऑक्साइड फैलाव (Bi2O3, शुद्धता: 99%)

- एल्युमिनियम टोल्यूनि फैलाव (अल, शुद्धता: 99.99%, एपीएस: 80 एनएम)

- ज़िरकोनियम ऑक्साइड नैनोपार्टिकल फैलाव (ZrO2, शुद्धता: 99.9%, APS: 45-55 nm)

- आयरन ऑक्साइड नैनोपार्टिकल्स फैलाव (Fe2O3, शुद्धता: 99.9%, APS: 20-100 nm)

- ऑक्टाफेनिल सिल्सक्विओक्सेन फैलाव (ऑक्टाफेनिल पीओएसएस, शुद्धता: 99.99%)

- एलुमिना स्लरी पॉलिशिंग फैलाव

- स्वच्छ जल फैलाव (> 95%, व्यास: 1-2 मिमी, लंबाई: 5-15 मिमी)

- ऑक्टा अमोनियम पीओएसएस (C24H72Cl8N8O12Si8, 98.0%)

- ईडीए लिगैंड के साथ नाइओबियम नैनोपाउडर फैलाव (शुद्धता: > 99.9%, एपीएस: 80-100 एनएम)

- एल्युमिनियम पाउडर फैलाव (अल, शुद्धता: 99.99%, एपीएस: 80 एनएम)

- एंटीमनी टिन ऑक्साइड फैलाव (Ato, Sno2:Sb2O3= 90:10, 20 Wt%, 20-80 Nm)

- नाइओबियम डोप्ड टाइटेनियम डाइऑक्साइड फैलाव (Nb/TiO2, IPA, 99.9%, 2-5 ओम)

- सिल्वर कॉपर अलॉय फैलाव (Ag: Cu, शुद्धता: 99.9%, Aps: <80 Nm)

- कार्बन कंडक्टिव इंक फैलाव (शुद्धता: 99.9%, एपीएस: 80-100 एनएम)

- कॉपर नैनोपार्टिकल्स फैलाव

- गैलियम नैनोपार्टिकल्स फैलाव

- ऑक्टामेथिल पीओएसएस (ऑक्टामेथिलसिल्सेसक्विओक्सेन, शुद्धता: 99.99%)

- टाइटेनियम डाइऑक्साइड डिस्पर्सन कॉस्मेटिक (TiO2, रूटाइल, 99.9%, 30-50 एनएम)

- मैग्नीशियम नैनोपार्टिकल फैलाव (Mg, शुद्धता: 99.99%, APS: 80 nm)

- सिलिकॉन डाइऑक्साइड फैलाव (SiO2, जलीय फैलाव, अनाकार)

- जिंक ऑक्साइड स्लरी फैलाव (Zno, शुद्धता: 99.9%, एपीएस: 50-80 एनएम)

- यूरोपियम डोपेड जिंक ऑक्साइड फैलाव

- कार्बन नैनो फाइबर फैलाव ऑर्गेनिक सॉल्वेंट

- निकेल ऑक्साइड फैलाव (निओ, बुटानॉल, शुद्धता: 99.9%, एपीएस: 50 एनएम)

- टाइटेनियम डाइऑक्साइड नैनोपार्टिकल्स फैलाव (Tio2, रूटाइल, 99.9%, 15-30 एनएम)

- सेरियम ऑक्साइड नैनोपार्टिकल फैलाव

- सिल्वर नैनो वाटर डिस्पर्सन (Ag, शुद्धता: 99.99%, APS: <80nm)

- पारदर्शी प्रवाहकीय स्याही फैलाव

- जिंक कॉपर कोर शेल फैलाव (Zncu, शुद्धता: 99.99% Aps: 40 Nm)

- एल्यूमिना फैलाव (Al2O3 फैलाव)

- ज़िरकोनिया स्लरी पॉलिशिंग (Zro2, शुद्धता: 99.9%, एपीएस: 50-80 एनएम)

- एपॉक्सीसाइक्लोहेक्सिल पॉस {(C8H13On) n (SiO1.5) n 99.99%}

- जिंक नैनोपार्टिकल्स फैलाव (Zn, शुद्धता: 99.99%, Aps: 50 Nm)

- बोरॉन नाइट्राइड नैनोपार्टिकल्स फैलाव (Bn, Aps: 80-100 Nm)

- Zno नैनोपार्टिकल फैलाव (जिंक ऑक्साइड, 99.9%, 30-40 Nm)

- ग्राफीन फैलाव ऑर्गेनिक सॉल्वेंट (C, शुद्धता: > 98%, हाइड्रोफोबिक)

- गोल्ड नैनोपार्टिकल्स फैलाव (Au, शुद्धता: 99.99%, APS: <10 nm)

- एल्युमिनियम ऑक्साइड फैलाव (Al2O3, गामा, 99.99%, 20-30 एनएम)

- इलेक्ट्रोड फिल्म्स वेफर्स और लक्ष्य

- सिलिकॉन कार्बाइड वेफर्स एन-टाइप (फॉस्फोरस डोपेड)

- सिलिकॉन डाइऑक्साइड लेयर के साथ सिलिकॉन वेफर

- सिलिकॉन वेफर्स (डोपेड और अनडॉप्ड)

- प्लेटिनम और गोल्ड कोटेड सिलिकॉन वेफर

- माइक्रोक्रिस्टलिन सेल्युलोज वेफर

- सिलिकॉन वेफर 6 इंच (पी टाइप, बोरॉन डोपेड)

- सिलिकॉन वेफर अनडॉप्ड

- सिलिकॉन जर्मेनियम वेफर्स

- सेंसर स्क्रीन प्रिंटेड इलेक्ट्रोड

- नीलम वेफर सी प्लेन (Al2O3)

- एन डोपेड सिलिकॉन वेफर (4 इंच एन टाइप फॉस्फोरस डोपेड)

- नैनोस्ट्रक्चर्ड कार्बन स्क्रीन प्रिंटेड इलेक्ट्रोड

- प्लेटिनम कोटेड सिलिकॉन वेफर

- जर्मेनियम वेफर्स

- इलेक्ट्रोड

- आयताकार मेष स्टेम ग्रिड - निकेल

- स्क्वायर मेश ग्रिड्स - गोल्ड

- रेक्टैंगुलर मेश टेम ग्रिड्स - गोल्ड

- स्क्वायर मेश ग्रिड - निकेल

- समांतर बार ग्रिड - तांबा

- सेंसर स्क्रीन प्रिंटेड इलेक्ट्रोड

- आयताकार मेष स्टेम ग्रिड - निकेल

- रेक्टैंगुलर मेश टेम ग्रिड्स - कॉपर

- रेक्टैंगुलर मेश टेम ग्रिड्स - पैलेडियम

- रेक्टैंगुलर मेश टेम ग्रिड्स - कॉपर

- स्क्वायर मेश ग्रिड - पैलेडियम

- स्क्वायर मेश ग्रिड्स - गोल्ड

- वेफर्स

- बोरॉन डोप्ड सिलिकॉन वेफर

- सिलिकॉन वेफर सिलिकॉन डाइऑक्साइड परत

- सिलिकॉन जर्मेनियम वेफर्स

- सिलिकॉन वेफर 6 इंच

- सिलिकॉन कार्बाइड वेफर्स

- सिलिकॉन वेफर अनडॉप्ड

- डोप्ड सिलिकॉन वेफर

- नीलमणि वेफर्स

- जर्मेनियम वेफर

- माइक्रोक्रिस्टलिन सेल्युलोज वेफर

- लेपित सिलिकॉन वेफर गोल्ड/सिल्वर/प्लैटिनम/क्रोमियम

- एन डोप्ड सिलिकॉन वेफर

- फोम फ़ॉइल और कोटिंग्स

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- एल्युमिनियम फोम्स

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- पन्नी

- धात्विक फोम

- ग्राफीन नैनो संरचना

- 5 wt% (ग्राफीन नैनोप्लेटलेट्स और कार्बन नैनोट्यूब) पानी/एनएमपी फैलाव

- ग्राफीन वाटर सॉल्यूशन

- ब्लू ल्यूमिनेसेंट ग्राफीन क्वांटम डॉट्स

- 1.0-1.5 wt% ग्राफीन

- एमिनेटेड ग्राफीन क्वांटम डॉट्स

- लेसी कार्बन 300 मेश कॉपर टीईएम ग्रिड पर ग्राफीन

- अल्ट्रा-फाइन 2000 मेश कॉपर टीईएम ग्रिड पर ग्राफीन

- ग्राफीन नैनोप्लेटलेट्स पाउडर

- सिलिकॉन नाइट्राइड टीईएम ग्रिड पर ग्राफीन

- ग्राफीन ऑक्साइड

- ग्राफीन पाउडर

- ग्राफीन शीट

- 0.4-0.5 wt% ग्राफीन

- अल्ट्रा-फ्लैट थर्मल SiO2 सबस्ट्रेट पर ग्राफीन

- ग्राफीन नैनोप्लेटलेट्स इंडस्ट्रियल ग्रेड (ग्राफीन नैनोप्लेटलेट्स)

- 3 डी फ्रीस्टैंडिंग ग्राफीन फोम

- कार्बोक्सिलेटेड ग्राफीन क्वांटम डॉट्स

- SiO2 सबस्ट्रेट पर CVD ग्राफीन

- सिलिकॉन सबस्ट्रेट पर सीवीडी ग्राफीन

- पालतू सब्सट्रेट पर सीवीडी ग्राफीन

- 3 डी फ्रीस्टैंडिंग ग्राफीन फोम

- निकेल/कॉपर फोम पर 3 डी ग्राफीन

- कार्बोक्सिलेटेड ग्राफीन क्वांटम डॉट्स

- क्वार्ट्ज सबस्ट्रेट पर सीवीडी ग्राफीन

- पीईटी सबस्ट्रेट पर सीवीडी ग्राफीन

- ग्राफीन नैनोप्लेटलेट्स

- नाइट्रोजन-डॉप्ड ग्राफीन

- ग्राफीन ऑक्साइड में कमी

- कम किया हुआ ग्राफीन ऑक्साइड पाउडर

- कॉपर फ़ॉइल पर सीवीडी ग्राफीन

- क्वार्ट्ज सबस्ट्रेट पर सीवीडी ग्राफीन

- SiO2 सबस्ट्रेट पर CVD ग्राफीन

- हाइड्रॉक्सिलेटेड ग्राफीन क्वांटम डॉट्स

- प्रीट्रीटेड ग्राफीन-पीएमएमए कोटेड

- सीवीडी ग्राफीन

- ग्राफीन और ग्राफीन ऑक्साइड

- ग्राफीन नैनोप्लेटलेट्स

- ग्राफीन क्वांटम डॉट्स

- सूक्ष्म कण एवं चूर्ण

- वैनेडियम माइक्रो पाउडर

- मेसोपोरस कार्बन सामग्री

- मैग्नीशियम पाउडर

- गोल्ड पाउडर

- टैंटलम पाउडर

- मैंगनीज पाउडर

- आयरन माइक्रोपाउडर

- ज़िरकोनियम पाउडर

- सिलिकॉन नाइट्राइड पाउडर

- सिलिकॉन पाउडर

- ज़िंक पाउडर

- कॉपर पाउडर

- टिन पाउडर

- मोलिब्डेनम पेंटाक्लोराइड (मोलिब्डेनम क्लोराइड, MoCl5, 99%)

- ग्रेफाइट पाउडर

- बिस्मथ पाउडर

- मेसोपोरस कार्बन सामग्री

- टाइटेनियम पाउडर

- सॉफ्ट आयरन पाउडर

- बोरॉन पाउडर

- नियोडिमियम आयरन बोरॉन मैग्नेटिक पाउडर (NdFeB)

- ब्रास पाउडर

- पैलेडियम पाउडर

- कांसे का पाउडर

- मैंगनीज कार्बोनेट माइक्रो पार्टिकल्स पाउडर

- सल्फर पाउडर रेड एआर ग्रेड

- क्रोमियम पाउडर

- कोबाल्ट माइक्रो पाउडर

- नाइओबियम माइक्रोपाउडर

- मिल्ड कार्बन फाइबर पाउडर

- चाँदी का पाउडर

- निकेल पाउडर

- बिलीरुबिन पाउडर

- कैडमियम पाउडर

- नाइओबियम माइक्रो पाउडर

- बिस्मथ (III) सल्फाइड पाउडर

- एल्युमिनियम पाउडर

- नाइओबियम पेंटाक्लोराइड पाउडर

- स्टेनलेस स्टील पाउडर

- पारदर्शी प्रवाहकीय स्याही

- बिस्मथ एल्यूमीनियम पाउडर

- वित्त मंत्रालय

- यूरोपियम मेटल ऑर्गेनिक फ्रेमवर्क

- डिस्प्रोसियम मेटल ऑर्गेनिक फ्रेमवर्क

- आयरन मेटल ऑर्गेनिक फ्रेमवर्क

- निकेल बेस्ड मेटल ऑर्गेनिक फ्रेमवर्क

- मैंगनीज मेटल ऑर्गेनिक फ्रेमवर्क

- समैरियम मेटल ऑर्गेनिक फ्रेमवर्क

- एल्युमिनियम मेटल ऑर्गेनिक फ्रेमवर्क (AL-MIL-53)

- नैनोपोरस आयरन मेटल ऑर्गेनिक फ्रेमवर्क (MIL-89)

- टाइटेनियम मेटल ऑर्गेनिक फ्रेमवर्क (NH2-MIL-125 (Ti), शुद्धता: 99%, APS: 30-40um)

- फेरस मेटल ऑर्गेनिक फ्रेमवर्क (MIL-53)

- जिंक बेस्ड मेटल ऑर्गेनिक फ्रेमवर्क (Zn (MOF-177), शुद्धता: 99%, APS: 30-40um)

- वैनेडियम मेटल ऑर्गेनिक फ्रेमवर्क (V-MIL-47, शुद्धता: 99%, APS: 30-40um)

- क्रोमियम मेटल ऑर्गेनिक फ्रेमवर्क

- मिथाइलिमिडाजोल जिंक साल्ट एमओएफ

- टिन मेटल ऑर्गेनिक फ्रेमवर्क

- एल्युमिनियम मेटल ऑर्गेनिक फ्रेमवर्क

- ज़िरकोनियम मेटल ऑर्गेनिक फ्रेमवर्क

- मेटल ऑर्गेनिक फ्रेमवर्क

- टर्बियम मेटल ऑर्गेनिक फ्रेमवर्क

- कॉपर मेटल ऑर्गेनिक फ्रेमवर्क

- नैनो कण और नैनो पाउडर

- एर्बियम ऑक्साइड नैनोपार्टिकल्स

- एलुमिना नैनोपार्टिकल्स पाउडर

- क्रोमियम ऑक्साइड नैनोपाउडर

- कार्बन नैनोपाउडर

- डायमंड नैनोपार्टिकल्स

- युरोपियम ऑक्साइड नैनोपार्टिकल्स

- गोल्ड नैनोपार्टिकल्स

- एल्युमिनियम नाइट्राइड (AlN, 99.9%, 100 एनएम से कम)

- कॉपर ऑक्साइड नैनोपार्टिकल्स

- डिस्प्रोसियम ऑक्साइड नैनोपार्टिकल्स

- कोबाल्ट नैनोपार्टिकल्स

- टिन नैनोपार्टिकल्स पाउडर

- सिलिकॉन गोलाकार पाउडर

- सिल्वर नैनोपार्टिकल्स

- ज़िंक नैनोपार्टिकल्स

- कोबाल्ट फेराइट नैनोपार्टिकल्स

- ग्राफीन नैनोप्लेटलेट्स पाउडर

- क्रोमियम कार्बाइड नैनोपार्टिकल्स

- कैडमियम सेलेनाइड नैनोपार्टिकल्स

- एल्यूमीनियम हाइड्रॉक्साइड नैनोपार्टिकल्स

- मैंगनीज जिंक अलॉय नैनोपाउडर

- कम हाफ़नियम सामग्री के साथ ज़िरकोनियम ऑक्साइड पाउडर

- हेफ़नियम ऑक्साइड नैनोपार्टिकल्स

- कॉपर नैनोपार्टिकल्स

- बिस्मथ नैनोपाउडर

- टैंटलम नाइट्राइड नैनोपार्टिकल्स

- कैडमियम सल्फाइड नैनोपार्टिकल्स

- सैरियम ऑक्साइड नैनोपार्टिकल्स

- एल्यूमीनियम नैनोपार्टिकल्स (Al, > 99.9%, 50 एनएम)

- एल्यूमीनियम ऑक्साइड नैनोपार्टिकल्स (Al2O3, अल्फा, 99.9%, 200 एनएम)

- एंटीमनी टिन ऑक्साइड नैनोपार्टिकल्स 99.99% 10 एनएम पाउडर

- बेरियम आयरन ऑक्साइड (BAFe12O19, 99.9%, 200 एनएम)

- बेरियम सल्फेट (BaSO4, 99%, 200-500 एनएम)

- बेरियम टाइटनेट नैनोपार्टिकल्स (BaTiO3, घन, 99.9%, 100 एनएम)

- बोरॉन कार्बाइड नैनोपार्टिकल्स (B4C, 99.9%, 500 एनएम)

- बोरॉन नाइट्राइड नैनोपार्टिकल्स

- बोरॉन ऑक्साइड नैनोपार्टिकल्स

- बोरॉन ऑक्साइड नैनोपार्टिकल्स

- कैल्शियम कार्बोनेट नैनोपार्टिकल्स पाउडर

- गैडोलीनियम ऑक्साइड नैनोपार्टिकल्स

- ग्रेफाइट नैनोपार्टिकल्स

- इंडियम हाइड्रॉक्साइड नैनोपार्टिकल्स

- इंडियम ऑक्साइड नैनोपार्टिकल्स

- इंडियम टिन ऑक्साइड आईटीओ नैनोपार्टिकल्स

- आयरन नैनोपार्टिकल्स

- आयरन ऑक्साइड हाइड्रोक्साइड गोइथाइट नैनोपार्टिकल्स

- आयरन ऑक्साइड नैनोपार्टिकल्स

- आयरन ऑक्साइड नैनोपार्टिकल्स पाउडर

- लेण्टेनियुम ऑक्साइड नैनोपार्टिकल्स

- मैग्नीशियम हाइड्रॉक्साइड नैनोपार्टिकल्स

- मैग्नीशियम ऑक्साइड नैनोपार्टिकल्स

- मोलिब्डेनम नैनोपार्टिकल्स

- मोलिब्डेनम ऑक्साइड नैनोपार्टिकल्स

- नियोडिमियम ऑक्साइड नैनोपार्टिकल्स

- निकेल नैनोपार्टिकल्स

- निकेल ऑक्साइड नैनोपार्टिकल्स

- प्लेटिनम नैनोपार्टिकल्स

- टाइटेनियम नैनोपार्टिकल्स

- टाइटेनियम ऑक्साइड नैनोपार्टिकल्स एनाटेज़

- टाइटेनियम ऑक्साइड रूटाइल नैनोपार्टिकल्स

- टंगस्टन ऑक्साइड नैनोपार्टिकल्स

- कैडमियम ऑक्साइड नैनोपार्टिकल्स

- कैडमियम नैनोपाउडर

- सिलिका कोटेड एल्युमिनियम नैनो पाउडर

- एल्यूमीनियम नाइट्राइड नैनोपार्टिकल्स

- अॅल्युमिनियम ऑक्साइड नॅनोपार्टिकल्स

- एंटीमनी ऑक्साइड नैनोपार्टिकल्स

- बेरियम आयरन ऑक्साइड नैनोपार्टिकल्स

- बेरियम सल्फेट (BaSO4) नैनोपार्टिकल्स

- बेरियम टाइटनेट

- क्रोमियम नैनोपार्टिकल्स

- जिंक ऑक्साइड नैनोपार्टिकल्स

- यिट्रियम ऑक्साइड नैनोपार्टिकल्स

- टंगस्टन नैनोपार्टिकल्स

- यटरबियम फ्लोराइड नैनोपार्टिकल्स

- टंगस्टन कार्बाइड कोबाल्ट नैनोपार्टिकल्स

- नैनोरोड्स

- नैनो तार

- सिल्वर नैनोवायर (एजी नैनोवायर)

- निकेल हाइड्रोक्साइड नैनोवायर

- जिंक ऑक्साइड नैनोवायर

- आयरन नैनोवायर्स

- टाइटेनियम डाइऑक्साइड नैनोवायर

- मैंगनीज टंगस्टेट नैनोवायर

- सिलिकॉन कार्बाइड नैनोवायर

- लीड ज़िरकोनेट टाइटनेट नैनोवायर

- हाइड्रोक्सीपाटाइट नैनोवायर

- एल्युमिनियम ऑक्साइड नैनोवायर

- मैंगनीज ऑक्साइड नैनोवायर

- टाइटेनियम डाइऑक्साइड नैनोवायर

- सिलिकॉन वेफर सबस्ट्रेट पर सिलिकॉन नैनोवायर

- वैनेडियम ऑक्साइड नैनोवायर

- निकेल नैनोवायर्स

- कॉपर नैनोवायर

- कोबाल्ट नैनोवायर्स

- निकेल ऑक्साइड नैनोवायर

- टेल्यूरियम नैनोवायर

- टाइटेनियम ऑक्साइड एनाटेज़ नैनोवायर्स

- मैग्नीशियम ऑक्साइड नैनोवायर

- टंगस्टन ऑक्साइड नैनोवायर

- आयरन ऑक्साइड नैनोवायर

- कॉपर हाइड्रॉक्साइड नैनोवायर

- कोटिंग और मेम्ब्रेन ग्रेड टाइटेनियम ऑक्साइड नैनोवायर

- पोटेशियम ट्रिमोलिब्डेट नैनोवायर

- सोडियम अमोनियम ट्राई मोलिब्डेट नैनोवायर

- लीड नैनोवायर्स

- लीड टाइटनेट नैनोवायर्स

- गोल्ड नैनोवायर

- हाइड्रोक्सीपाटाइट नैनोवायर

- हाइली कंडक्टिंग सिल्वर नैनोवायर

- लेण्टेनियुम ऑक्साइड नैनोवायर्स

- आयरन ऑक्सीहाइड्रॉक्साइड नैनोवायर

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- क्वांटम डॉट्स

- ब्लू ल्यूमिनेसेंट हाइड्रोफिलिक ग्राफीन क्वांटम डॉट्स

- कैडमियम टेलुराइड क्वांटम डॉट्स

- INP ZNS क्वांटम डॉट्स

- एलईडी क्वांटम डॉट्स (जिंक सेलेनाइड/जिंक सल्फाइड क्वांटम डॉट्स)

- कैडमियम सल्फाइड/जिंक सल्फाइड क्वांटम डॉट्स

- ब्लू ल्यूमिनेसेंट हाइड्रोफोबिक ग्राफीन क्वांटम डॉट्स

- ब्लू ल्यूमिनेसेंट हाइड्रोफोबिक ग्राफीन क्वांटम डॉट्स (पाउडर)

- ZnCDSes मिश्र धातु क्वांटम डॉट्स

- इंडियम फॉस्फाइड/जिंक सल्फाइड क्वांटम डॉट्स (INP/ZNS) क्वांटम डॉट्स

- कार्बन COOH QDs

- ब्लू ल्यूमिनेसेंट हाइड्रोफिलिक ग्राफीन क्वांटम डॉट्स (पाउडर)

- जिंक सेलेनाइड/जिंक सल्फाइड क्वांटम डॉट्स

- मोलिब्डेनम डाइसल्फ़ाइड क्वांटम डॉट्स

- कैडमियम सल्फाइड क्वांटम डॉट्स

- एलईडी क्वांटम डॉट्स

- नैनोकणों को परिवर्तित करना

- चिपकाएँ और स्याही

- निकेल ऑक्साइड एनोड पेस्ट

- प्लेटिनम गोल्ड कंडक्टर पेस्ट

- सिल्वर पेस्ट

- प्लेटिनम पेस्ट स्क्रीन प्रिंट इंक

- कंडक्टिंग गोल्ड पेस्ट

- सिल्वर प्लेटिनम कंडक्टर पेस्ट

- येट्रिया स्टैबिलाइज्ड ज़िरकोनिया पेस्ट

- प्लेटिनम कंडक्टिंग पेस्ट

- स्क्रीन प्रिंटिंग के लिए गोल्ड पेस्ट

- स्क्रीन प्रिंटिंग इलेक्ट्रोड के लिए डाइलेक्ट्रिक पेस्ट

- टंगस्टन कंडक्टिंग पेस्ट

- कार्बन स्क्रीन प्रिंट पेस्ट और इंक

- टाइटेनियम डाइऑक्साइड पेस्ट

- सिल्वर-पैलेडियम कंडक्टिंग पेस्ट

- कॉपर पेस्ट

- सिल्वर कंडक्टिंग पेस्ट

- इलेक्ट्रोकैमिस्ट्री के लिए सिल्वर/सिल्वर क्लोराइड पेस्ट

- कार्बन ग्राफीन स्क्रीन प्रिंट इंक पेस्ट

- एल्युमिनियम ऑक्साइड पेस्ट

- स्क्रीन प्रिंटिंग के लिए इंसुलेटिंग पेस्ट

- अन्य विशिष्ट रसायन एवं सामग्री

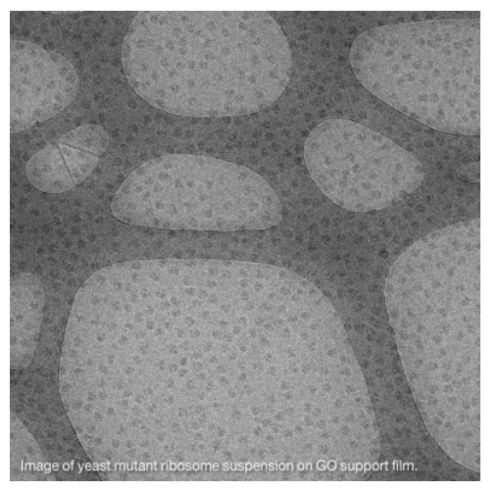

- 400mesh Cu ग्रिड (25 का पैक) पर लेसी कार्बन पर ग्राफीन ऑक्साइड सपोर्ट फिल्म

- 100 ग्रिड के लिए ग्रिड स्टोरेज बॉक्स

- कम हाफ़नियम सामग्री के साथ ज़िरकोनियम ऑक्साइड पाउडर

- एज़ो कोटेड ग्लास

- 400 मेश ग्रिड कॉपर पर कार्बन फिल्म्स (50 का पैक)

- PVDF पॉली पाउडर (विनाइलिडीन फ्लोराइड)

- 300 मेश गोल्ड ग्रिड पर कार्बन फिल्म्स (50 का पैक)

- 300 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (50 का पैक)

- हेक्सागोनल मेश ग्रिड - निकेल

- हाइड्रोथर्मल आटोक्लेव रिएक्टर

- हाइड्रोथर्मल आटोक्लेव रिएक्टर

- FTO कोटेड ग्लास

- हाइड्रोथर्मल आटोक्लेव रिएक्टर

- 300 मेश कॉपर ग्रिड्स पर होली कार्बन फिल्म्स (50 का पैक)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- 300 मेश ग्रिड कॉपर पर कार्बन फिल्म्स (50 का पैक)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- एज़ो कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- वेफर चिमटी टाइप 46WF

- आगर ग्रिड्स 200 मेश गोल्ड सेंटर मार्क 3.05 मिमी (50 की ट्यूब)

- कॉपर ग्रिड्स पर कार्बन फिल्में

- Dumont N5AC चिमटी के साथ रोटरी ग्रिड स्टोरेज बॉक्स किट

- चिपकने वाला कार्बन टेप 8 मिमी x 20 मीटर

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- सिल्वर प्लेटिनम एलॉय पाउडर

- 300 मेश ग्रिड कॉपर पर कार्बन फिल्म्स (25 का पैक)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- वेफर चिमटी टाइप 4WL

- वेफर चिमटी टाइप 8WF

- 400 मेश ग्रिड कॉपर पर कार्बन फिल्म्स (25 का पैक)

- 200 मेश कॉपर ग्रिड्स पर होली कार्बन फिल्म्स (50 का पैक)

- टाइप 92 पॉलीमाइड फिल्म टेप - 12 मिमी x 33 मीटर

- कॉपर ग्रिड्स पर कार्बन फिल्में

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- सोडियम हाइपोक्लोराइट

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- कार्बन टाइप-बी 300 मेश पैक ऑफ 50

- 300 मेश कॉपर पर फॉर्मवार/कार्बन (50 का पैक)

- लीट सी कंडक्टिंग कार्बन सीमेंट (30 मिली)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- 200 मेश गोल्ड ग्रिड पर कार्बन फिल्म्स (50 का पैक)

- लीट सी थिनर्स (30 मि. ली.)

- सिलिकॉन वेफर, चिप्स 5 x 5 मिमी। (लगभग 270 चिप्स प्रति वेफर)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- AZO कोटेड ग्लास

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- कोबाल्ट आयरन अलॉय पाउडर (नैनो और माइक्रोन पार्टिकल साइज)

- टाइटेनियम एल्यूमीनियम वैनेडियम Ti-6Al-4V गोलाकार पाउडर

- 300 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (25 का पैक)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास

- 96 ग्रिड के लिए ग्रिड स्टोरेज बॉक्स

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- फॉर्मवार/कार्बन ऑन 200 मेश कॉपर (50 का पैक)

- 400 मेश कॉपर पर फॉर्मवार/कार्बन (50 का पैक)

- आगर ग्रिड्स 200 मेश कॉपर सेंटर मार्क 3.05 मिमी (100 की ट्यूब)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- हाइड्रोथर्मल आटोक्लेव रिएक्टर

- एज़ो कोटेड ग्लास

- ग्रिड स्टोरेज बॉक्स

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- 300 मेश कॉपर ग्रिड्स पर होली कार्बन फिल्म्स (25 का पैक)

- पहचान संख्या के साथ ग्रिड स्टोरेज बॉक्स

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- आगर ग्रिड्स 300 मेश कॉपर 3.05 मिमी (100 की ट्यूब)

- एज़ो कोटेड ग्लास

- 25 ग्रिड (Pk10) के लिए सीरियलाइज्ड रोटरी ग्रिड स्टोरेज बॉक्स

- कॉपर फ़ॉइल कंडक्टिव टेप

- एल्यूमीनियम 8mm x 20m के साथ कार्बन टेप

- 400 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (50 का पैक)

- आगर ग्रिड्स 300 मेश गोल्ड 3.05 मिमी (50 की ट्यूब)

- 200 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (50 का पैक)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- फ्लोरीन डोपेड टिन ऑक्साइड कोटेड ग्लास

- पिनाटॉक्सिन-जी कैस: 1312711-74-2

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- सिल्वर टिन अलॉय पाउडर

- हेक्सागोनल मेश ग्रिड - कॉपर

- समांतर बार ग्रिड - तांबा

- समांतर बार ग्रिड - तांबा

- समांतर बार ग्रिड्स -पैलेडियम

- समांतर बार ग्रिड्स -पैलेडियम

- समांतर बार ग्रिड्स -पैलेडियम

- समांतर बार ग्रिड्स -पैलेडियम

- फोल्डिंग ग्रिड - कॉपर

- फोल्डिंग ग्रिड - कॉपर

- फोल्डिंग ग्रिड - पैलेडियम

- फोल्डिंग ग्रिड - पैलेडियम

- फोल्डिंग ग्रिड - निकेल

- फोल्डिंग ग्रिड - निकेल

- फोल्डिंग ग्रिड्स - गोल्ड

- हेक्सागोनल मेश ग्रिड - निकेल

- हेक्सागोनल मेश ग्रिड - निकेल

- हेक्सागोनल मेश ग्रिड - निकेल

- हेक्सागोनल मेश ग्रिड - निकेल

- हेक्सागोनल मेश ग्रिड - निकेल

- हेक्सागोनल मेश ग्रिड - गोल्ड

- हेक्सागोनल मेश ग्रिड - गोल्ड

- हेक्सागोनल मेश ग्रिड - गोल्ड

- हेक्सागोनल मेश ग्रिड - गोल्ड

- हेक्सागोनल मेश ग्रिड - गोल्ड

- हेक्सागोनल मेश ग्रिड - गोल्ड

- हेक्सागोनल मेश ग्रिड - गोल्ड

- ट्रिपल स्लॉट ग्रिड

- सिंगल होल टेम ग्रिड्स - कॉपर

- सिंगल होल टेम ग्रिड्स - पैलेडियम

- सिंगल होल टेम ग्रिड - कॉपर/पैलेडियम

- सिंगल होल टेम ग्रिड - निकेल

- सिंगल होल टेम ग्रिड्स -निकेल

- सिंगल होल टेम ग्रिड्स -निकेल

- सिंगल होल टेम ग्रिड्स -निकेल

- पार्टिकल एनालिसिस ग्रिड्स कॉपर

- सिंगल होल टेम ग्रिड्स - गोल्ड

- सिंगल होल टेम ग्रिड्स -गोल्ड

- टैब्ड ग्रिड - तांबा

- टैब्ड ग्रिड - निकेल

- टैब्ड ग्रिड - सोना

- विशेष धातु ग्रिड - अल्युमीनियम

- विशेष धातु ग्रिड - अल्युमीनियम

- विशेष धातु ग्रिड - अल्युमीनियम

- विशेष धातु ग्रिड - अल्युमीनियम

- विशेष धातु ग्रिड - अल्युमीनियम

- विशेष धातु ग्रिड - मोलिब्डेनम

- विशेष धातु ग्रिड - मोलिब्डेनम

- विशेष धातु ग्रिड - मोलिब्डेनम

- विशेष धातु ग्रिड - मोलिब्डेनम

- विशेष धातु ग्रिड - मोलिब्डेनम

- विशेष धातु ग्रिड -मोलिब्डेनम

- स्पेशल मेटल ग्रिड-मोलिब्डेनम

- विशेष धातु ग्रिड-मोलिब्डेनम

- स्पेशल मेटल ग्रिड-मोलिब्डेनम

- विशेष धातु ग्रिड - मोलिब्डेनम

- विशेष धातु ग्रिड - मोलिब्डेनम

- विशेष धातु ग्रिड - मोलिब्डेनम

- स्पेशल मेटल ग्रिड - स्टेनलेस स्टील

- स्पेशल मेटल ग्रिड - स्टेनलेस स्टील

- स्पेशल मेटल ग्रिड - टाइटेनियम

- स्पेशल मेटल ग्रिड - टाइटेनियम

- स्पेशल मेटल ग्रिड्स -टाइटेनियम

- स्पेशल मेटल ग्रिड्स - टाइटेनियम

- स्पेशल मेटल ग्रिड्स - टाइटेनियम

- स्पेशल मेटल ग्रिड्स - टाइटेनियम

- स्पेशल मेटल ग्रिड्स - टाइटेनियम

- फाइंडर ग्रिड - 200 मेष (6 ग्रिड)

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - डायमंड

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- कॉपर ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- निकेल ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- गोल्ड ग्रिड्स पर कार्बन फिल्में

- अल्ट्रा-थिन कार्बन सपोर्ट फिल्म, 3nm

- अल्ट्रा-थिन कार्बन सपोर्ट फिल्म, 3nm

- अल्ट्रा-थिन कार्बन सपोर्ट फिल्म, 3nm - लेसी कार्बन पर

- स्टेनलेस स्टील मेष 150 मिमी x 150 मिमी

- 200 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (50 का पैक)

- 200 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (25 का पैक)

- 300 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (50 का पैक)

- 300 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (25 का पैक)

- 400 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (50 का पैक)

- 400 मेश कॉपर ग्रिड्स पर लेसी कार्बन फिल्म्स (25 का पैक)

- H7 फाइंडर ग्रिड पर लेसी कार्बन फिल्म्स। तांबा (50 का पैक)

- H7 फाइंडर ग्रिड पर लेसी कार्बन फिल्म्स। तांबा (25 का पैक)

- 200 मेश निकेल पर लेसी कार्बन फिल्म्स (50 का पैक)

- 200 मेश निकेल पर लेसी कार्बन फिल्म्स (25 का पैक)

- 300 मेश निकेल पर लेसी कार्बन फिल्म्स (50 का पैक)

- 300 मेश निकेल पर लेसी कार्बन फिल्म्स (25 का पैक)

- 400 मेश निकेल पर लेसी कार्बन फिल्म्स (50 का पैक)

- 400 मेश निकेल पर लेसी कार्बन फिल्म्स (25 का पैक)

- H7 फाइंडर ग्रिड पर लेसी कार्बन फिल्म्स। निकेल (50 का पैक)

- H7 फाइंडर ग्रिड पर लेसी कार्बन फिल्म्स। निकेल (25 का पैक)

- 200 मेश गोल्ड पर लेसी कार्बन फिल्म्स (50 का पैक)

- 200 मेश गोल्ड पर लेसी कार्बन फिल्म्स (25 का पैक)

- 300 मेश गोल्ड पर लेसी कार्बन फिल्म्स (50 का पैक)

- 300 मेश गोल्ड पर लेसी कार्बन फिल्म्स (25 का पैक)

- 400 मेश गोल्ड पर लेसी कार्बन फिल्म्स (50 का पैक)

- 400 मेश गोल्ड पर लेसी कार्बन फिल्म्स (25 का पैक)

- H7 फाइंडर ग्रिड पर लेसी कार्बन फिल्म्स। गोल्ड (50 का पैक)

- H7 फाइंडर ग्रिड पर लेसी कार्बन फिल्म्स। गोल्ड (25 का पैक)

- 200 मेश कॉपर ग्रिड्स पर होली कार्बन फिल्म्स (50 का पैक)

- 200 मेश कॉपर ग्रिड्स पर होली कार्बन फिल्म्स (25 का पैक)

- 300 मेश कॉपर ग्रिड्स पर होली कार्बन फिल्म्स (50 का पैक)

- 300 मेश कॉपर ग्रिड्स पर होली कार्बन फिल्म्स (25 का पैक)

- 400 मेश कॉपर ग्रिड्स पर होली कार्बन फिल्म्स (50 का पैक)

- 400 मेश कॉपर ग्रिड्स पर होली कार्बन फिल्म्स (25 का पैक)

- H7 फाइंडर ग्रिड्स कॉपर पर होली कार्बन फिल्म्स (50 का पैक)

- H7 फाइंडर ग्रिड्स कॉपर पर Holey Carbon Films (25 का पैक)

- 200 मेश निकेल पर होली कार्बन फिल्म्स (50 का पैक)

- 200 मेश निकेल पर होली कार्बन फिल्म्स (25 का पैक)

- 300 मेश निकेल पर होली कार्बन फिल्म्स (50 का पैक)

- 300 मेश निकेल पर होली कार्बन फिल्म्स (25 का पैक)

- 400 मेश निकेल पर होली कार्बन फिल्म्स (50 का पैक)

- 400 मेश निकेल पर होली कार्बन फिल्म्स (25 का पैक)

- H7 फाइंडर ग्रिड्स निकेल पर होली कार्बन फिल्म्स (50 का पैक)

- H7 फाइंडर ग्रिड्स निकेल पर होली कार्बन फिल्म्स (25 का पैक)

- होली कार्बन फिल्म्स ऑन 200 मेश गोल्ड (50 का पैक)

- होली कार्बन फिल्म्स ऑन 200 मेश गोल्ड (25 का पैक)

- 300 मेश गोल्ड पर होली कार्बन फिल्म्स (50 का पैक)

- 300 मेश गोल्ड पर होली कार्बन फिल्म्स (25 का पैक)

- 400 मेश गोल्ड पर होली कार्बन फिल्म्स (50 का पैक)

- 400 मेश गोल्ड पर होली कार्बन फिल्म्स (25 का पैक)

- H7 फाइंडर ग्रिड्स गोल्ड पर होली कार्बन फिल्म्स (50 का पैक)

- H7 फाइंडर ग्रिड्स गोल्ड पर होली कार्बन फिल्म्स (25 का पैक)

- Formvar on 3mm 75 मेश कट ग्रिड (25 का पैक)

- Formvar on 3mm 100 मेश कट ग्रिड (25 का पैक)

- फॉर्मवर ऑन 3mm 200 मेश कट ग्रिड (25 का पैक)

- फॉर्मवर ऑन 3mm 300 मेश कट ग्रिड (25 का पैक)

- फॉर्मवर ऑन 3mm 400 मेश कट ग्रिड (25 का पैक)

- ग्रिड के साथ 3 मिमी F1 फाइंडर फॉर्म (25 का पैक)

- ग्रिड के साथ 3 मिमी H7 फाइंडर का प्रारूप (25 का पैक)

- Formvar on 3mm 75 मेश नी ग्रिड (25 का पैक)

- Formvar on 3mm 100 मेश नी ग्रिड (25 का पैक)

- फॉर्मवर ऑन 3mm 200 मेश नी ग्रिड्स (25 का पैक)

- फॉर्मवर ऑन 3mm 300 मेश नी ग्रिड (25 का पैक)

- फॉर्मवर ऑन 3mm 400 मेश नी ग्रिड (25 का पैक)

- 3 मिमी F1 फाइंडर नी ग्रिड पर फ़ॉर्मवार (25 का पैक)

- 3mm H7 फाइंडर नी ग्रिड पर फॉर्मवर (25 का पैक)

- फॉर्मवर ऑन 3mm 100 मेश एयू ग्रिड्स (25 का पैक)

- फॉर्मवर ऑन 3mm 200 मेश एयू ग्रिड्स (25 का पैक)

- फॉर्मवर ऑन 3mm 300 मेश एयू ग्रिड्स (25 का पैक)

- फॉर्मवर ऑन 3mm 400 मेश एयू ग्रिड्स (25 का पैक)

- फॉर्मवर ऑन 2mm x 1mm Au स्लॉट ग्रिड (25 का पैक)

- 3 मिमी F1 फाइंडर एयू ग्रिड पर प्रारूप (25 का पैक)

- 3mm H7 फाइंडर एयू ग्रिड पर फॉर्मवर (25 का पैक)

- 75 मेश कॉपर पर फॉर्मवार/कार्बन (50 का पैक)

- 75 मेश कॉपर पर फॉर्मवार/कार्बन (25 का पैक)

- फॉर्मवार/कार्बन ऑन 200 मेश कॉपर (50 का पैक)

- फॉर्मवार/कार्बन ऑन 200 मेश कॉपर (25 का पैक)

- 300 मेश कॉपर पर फॉर्मवार/कार्बन (50 का पैक)

- 400 मेश कॉपर पर फॉर्मवार/कार्बन (25 का पैक)

- 2mmx1mm स्लॉट कॉपर ग्रिड पर फॉर्मवार/कार्बन (50 का पैक)

- F1 कॉपर ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (50 का पैक)

- F1 कॉपर ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (25 का पैक)

- कॉपर H7 ग्रिड (Pk 50) पर फॉर्मवार/कार्बन फिल्म्स

- कॉपर H7 ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (25 का पैक)

- 75 मेश निकेल पर फॉर्मवार/कार्बन (50 का पैक)

- 75 मेश निकेल पर फॉर्मवार/कार्बन (25 का पैक)

- फॉर्मवार/कार्बन ऑन 100 मेश निकेल (50 का पैक)

- फॉर्मवार/कार्बन ऑन 100 मेश निकेल (25 का पैक)

- फॉर्मवार/कार्बन ऑन 100 मेश निकेल (25 का पैक)

- फॉर्मवार/कार्बन ऑन 200 मेश निकेल (25 का पैक)

- 300 मेश निकेल पर फॉर्मवार/कार्बन (50 का पैक)

- 400 मेश निकेल पर फॉर्मवार/कार्बन (50 का पैक)

- 400 मेश निकेल पर फॉर्मवार/कार्बन (25 का पैक)

- 2 मिमी x 1 मिमी निकेल स्लॉट पर फॉर्मवार/कार्बन (50 का पैक)

- 2mmx1mm निकेल स्लॉट पर फॉर्मवार/कार्बन (25 का पैक)

- F1 निकेल ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (25 का पैक)

- F1 निकेल ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (50 का पैक)

- H7 निकेल ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (50 का पैक)

- H7 निकेल ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (25 का पैक)

- 75 मेश गोल्ड पर फॉर्मवार/कार्बन (25 का पैक)

- फॉर्मवार/कार्बन ऑन 100 मेश गोल्ड (50 का पैक)

- फॉर्मवार/कार्बन ऑन 100 मेश गोल्ड (25 का पैक)

- फॉर्मवार/कार्बन ऑन 200 मेश गोल्ड (50 का पैक)

- फॉर्मवार/कार्बन ऑन 200 मेश गोल्ड (25 का पैक)

- फॉर्मवार/कार्बन ऑन 300 मेश गोल्ड (50 का पैक)

- 300 मेश गोल्ड पर फॉर्मवार/कार्बन (25 का पैक)

- 400 मेश गोल्ड पर फॉर्मवार/कार्बन (50 का पैक)

- 400 मेश गोल्ड पर फॉर्मवार/कार्बन (25 का पैक)

- 2mmx1mm गोल्ड स्लॉट पर फॉर्मवार/कार्बन (50 का पैक)

- 2mmx1mm गोल्ड स्लॉट पर फॉर्मवार/कार्बन (25 का पैक)

- F1 गोल्ड ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (50 का पैक)

- F1 गोल्ड ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (25 का पैक)

- H7 गोल्ड ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (50 का पैक)

- H7 गोल्ड ग्रिड पर फॉर्मवार/कार्बन फिल्म्स (25 का पैक)

- 400mesh Cu ग्रिड (25 का पैक) पर लेसी कार्बन पर ग्राफीन ऑक्साइड सपोर्ट फिल्म

- 300mesh Cu ग्रिड (10 का पैक) पर क्वांटिफ़ोइल R2/2 पर ग्राफीन ऑक्साइड सपोर्ट फिल्म

- क्वांटिफ़ोइल R1.2/1.3 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल R1.2/1.3 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल R1.2/1.3 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/1 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/1 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/1 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/2 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/2 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/2 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/2 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/2 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/4 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/4 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल आर 2/4 होली कार्बन फिल्म्स - सर्कुलर

- अल्ट्रा यूफोइल होली गोल्ड फिल्म्स

- क्वांटिफ़ोइल R3.5/1 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल R3.5/1 होली कार्बन फिल्म्स - सर्कुलर

- क्वांटिफ़ोइल R3.5/1 होली कार्बन फिल्म्स - सर्कुलर

- 25 ग्रिड के लिए रोटरी ग्रिड स्टोरेज बॉक्स

- 25 ग्रिड के लिए सीरियलाइज्ड रोटरी ग्रिड स्टोरेज बॉक्स

- 25 ग्रिड के लिए रोटरी ग्रिड स्टोरेज बॉक्स (Pk10)

- 25 ग्रिड (Pk10) के लिए सीरियलाइज्ड रोटरी ग्रिड स्टोरेज बॉक्स

- Dumont N5AC चिमटी के साथ रोटरी ग्रिड स्टोरेज बॉक्स किट

- ड्यूमॉन्ट एचपी 5 एसएस चिमटी के साथ रोटरी ग्रिड स्टोरेज बॉक्स किट

- मेटल क्रायो ग्रिड बॉक्स

- मेटल क्रायो ग्रिड बॉक्स

- 6 TEM ग्रिड के लिए रोटरी ग्रिड स्टोरेज बॉक्स

- ग्रिड स्टोरेज बॉक्स

- ग्रिड स्टोरेज बॉक्स

- पहचान संख्या के साथ ग्रिड स्टोरेज बॉक्स

- ग्रिड स्टोरेज बॉक्स

- 96 ग्रिड के लिए ग्रिड स्टोरेज बॉक्स

- BEEM डायल-ए-ग्रिड स्टोरेज बॉक्स

- ग्रिड स्टोरेज बॉक्स

- 50 टैब्ड ग्रिड के लिए स्टोरेज बॉक्स

- लिफ्ट-आउट ग्रिड स्टोरेज बॉक्स

- FIB ग्रिड स्टोरेज बॉक्स

- क्रायो टेम ग्रिड बॉक्स

- क्रायो टेम ग्रिड बॉक्स

- क्रायो टेम ग्रिड बॉक्स

- मल्टीकलर क्रायो ग्रिड बॉक्स हैंडलिंग रॉड्स

- क्रायो एम राउंड स्टोरेज बॉक्स, 4 होल, टू फिट फी विट्रोबोट

- एपॉक्सी क्योर

- एपॉक्सी क्योर

- Loctite 460 सैंपल बॉन्डिंग एडहेसिव, 50g।

- एपोकविक फास्ट क्योरिंग एपॉक्सी

- एपोथिन 2 लो विस्कोसिटी एपॉक्सी

- एपोथिन 2 लो विस्कोसिटी एपॉक्सी

- नमूना माउंटिंग वैक्स

- लैकोमाइट वार्निश और रिमूवर

- डायमंड पॉलिशिंग पेस्ट लुब्रिकेंट

- केमेट डायमंड पॉलिशिंग पेस्ट

- केमेट डायमंड पॉलिशिंग पेस्ट

- केमेट डायमंड पॉलिशिंग पेस्ट

- अपघर्षक पाउडर

- अल्ट्राप्रेप डायमंड लैपिंग फिल्म्स

- स्कैन-डिया एम्बेडिंग सिस्टम

- वेफर-माउंट एडहेसिव्स

- क्विकस्टिक टेम्परेरी माउंटिंग वैक्स, 20 का पैक

- डिस्पोजेबल स्टिरर्स

- पॉलीप्रोपाइलीन कप

- पॉलीप्रोपाइलीन पेट्री डिश

- पॉलिशिंग क्लॉथ्स एंड डिस्क

- अपघर्षक स्ट्रिप्स - डायमंड

- अपघर्षक स्ट्रिप्स - एल्युमिनियम ऑक्साइड

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- इंडियम टिन ऑक्साइड कोटेड ग्लास (ITO)

- नेफियन-117 समाधान

- दुर्लभ पृथ्वी धातुएँ

- यिट्रियम ऑक्साइड (Y2O3) माइक्रोन पाउडर

- डिस्प्रोसियम ऑक्साइड (Dy2O3) माइक्रोन पाउडर

- लान्थेनम ट्राइफ्लोराइड (LaF3) नैनोपाउडर/नैनोपार्टिकल्स

- लैंथेनम एलुमिनेट (एलएएलओए) पाउडर माइक्रोन और नैनो साइज

- लैंथेनम हेक्साबोराइड (LaB6) माइक्रोन पाउडर

- यिट्रियम एल्युमिनेट (Y3Al5O12) नैनोपाउडर/नैनोपार्टिकल्स

- सेरियम (Ce) माइक्रोन पाउडर

- डिस्प्रोसियम (डाई) माइक्रोन पाउडर

- अर्बियम (एर) माइक्रोन पाउडर

- युरोपियम (Eu) माइक्रोन पाउडर

- गैडोलीनियम (Gd) माइक्रोन पाउडर

- होल्मियम (हो) माइक्रोन पाउडर

- लैंथेनम (La) माइक्रोन पाउडर

- लुटेटियम (लू) माइक्रोन पाउडर

- नियोडिमियम (एनडी) माइक्रोन पाउडर

- प्रेसियोडीमियम (पीआर) माइक्रोन पाउडर

- समैरियम (Sm) माइक्रोन पाउडर

- स्कैंडियम (Sc) माइक्रोन पाउडर

- टर्बियम (Tb) माइक्रोन पाउडर

- थुलियम (टीएम) माइक्रोन पाउडर

- यटरबियम (Yb) माइक्रोन पाउडर

- यिट्रियम (Y) माइक्रोन पाउडर

- सेरियम ऑक्साइड (CeO2) माइक्रोन पाउडर

- सेरियम ऑक्साइड (CeO2) नैनोपाउडर/नैनोपार्टिकल्स

- डिस्प्रोसियम ऑक्साइड (Dy2O3) नैनोपाउडर/नैनोपार्टिकल्स

- एर्बियम ऑक्साइड (Er2O3) माइक्रोन पाउडर

- एर्बियम ऑक्साइड (Er2O3) नैनोपाउडर/नैनोपार्टिकल्स

- यूरोपियम ऑक्साइड (Eu2O3) माइक्रोन पाउडर

- युरोपियम ऑक्साइड (Eu2O3) नैनोपाउडर/नैनोपार्टिकल्स

- गैडोलीनियम ऑक्साइड (Gd2O3) माइक्रोन पाउडर

- गैडोलीनियम ऑक्साइड (Gd2O3) नैनोपाउडर/नैनोपार्टिकल्स

- होल्मियम ऑक्साइड (Ho2O3) माइक्रोन पाउडर

- लेण्टेनियुम ऑक्साइड (La2O3) माइक्रोन पाउडर

- लेण्टेनियुम ऑक्साइड (La2O3) नैनोपाउडर/नैनोपार्टिकल्स

- लुटेटियम ऑक्साइड (Lu2O3) माइक्रोन पाउडर

- नियोडिमियम ऑक्साइड (Nd2O3) माइक्रोन पाउडर

- नियोडिमियम ऑक्साइड (Nd2O3) नैनोपाउडर/नैनोपार्टिकल्स

- प्रेसियोडीमियम ऑक्साइड (Pr6O11) माइक्रोन पाउडर

- प्रेसियोडीमियम ऑक्साइड (Pr6O11) नैनोपाउडर/नैनोपार्टिकल्स

- समैरियम ऑक्साइड (Sm2O3) माइक्रोन पाउडर

- समैरियम ऑक्साइड (Sm2O3) नैनोपाउडर/नैनोपार्टिकल्स

- स्कैंडियम ऑक्साइड (Sc2O3) माइक्रोन पाउडर

- टर्बियम ऑक्साइड (Tb4O7) माइक्रोन पाउडर

- टर्बियम ऑक्साइड (Tb4O7) नैनोपाउडर/नैनोपार्टिकल्स

- थुलियम ऑक्साइड (Tm2O3) माइक्रोन पाउडर

- यिट्रियम ऑक्साइड (Y2O3) नैनोपाउडर/नैनोपार्टिकल्स

- सेरियम (Ce) माइक्रोन पाउडर

- डिस्प्रोसियम (डाई) माइक्रोन पाउडर

- एमएक्सईएन और एमएक्सईएन पाउडर

- Mo3AlC2 मैक्सईन पाउडर

- Ti3AlC2 एमएक्सईएन

- Ti2C मैक्सीन पाउडर

- Ti2Alc मैक्सीन पाउडर

- Ti3SiC2 मैक्सईन पाउडर

- Ti3C2Tx MXene कुछ परत फैलाव समाधान

- V2C मैक्सीन पाउडर

- Ti3C2Tx (MXene) बहुपरत नैनोफ्लेक

- Nb2Alc मैक्सीन पाउडर

- Ta4AlC3 मैक्सईन पाउडर

- Mo2Ga2C मैक्सईन पाउडर

- टाइटेनियम कार्बाइड (Ti3C2) MXene फ्रीस्टैंडिंग थिन फिल्म्स

- Ti3C2Tx (MXene) पतली परत फैलाव समाधान

- V2Alc मैक्सीन पाउडर

- Nb4AlC3 मैक्सीन पाउडर

- V4AlC3 मैक्सईन पाउडर

- Mn2Alc मैक्सीन पाउडर

- Ti3AlC2 मैक्सईन पाउडर

- Cr2Alc मैक्सीन पाउडर

- NB2CTx MXene मल्टीलेयर नैनोफ्लेक

- Ti2AlC सिरेमिक सामग्री

- Ti2AlN मैक्सईन पाउडर

- Ti3C2Tx (MXene) नैनोसाइज पतली परत फैलाव

- Ti3C2Tx (MXene) पतली परत फैलाव समाधान

- Ti3C2Tx मैक्सीन फ्यू लेयर नैनोफ्लेक

- कृत्रिम पसीना

- कृत्रिम एक्राइन पसीना - स्थिर नहीं (BZ110)

- कृत्रिम एक्राइन पसीना - स्थिर (BZ112)

- कृत्रिम एक्राइन पसीना - स्थिर 1000 मिलीलीटर (BZ113)

- कृत्रिम एक्राइन पसीना - स्थिर 200ml (BZ111)

- कृत्रिम एक्क्राइन पसीना कस्टम पीएच - स्थिर नहीं। 200ml (BZ114)

- कृत्रिम एक्राइन पसीना कस्टम पीएच - स्थिर। 200ml (BZ115)

- आर्टिफिशियल एक्क्राइन पर्सपिरेशन GMW14334 पसीना, 2-भाग क्षारीय गैर-स्थिर (BZ160)

- कृत्रिम एक्क्राइन पसीना, अम्लीय, कस्टम पीएच, स्थिर (BZ157)

- आर्टिफिशियल एक्क्राइन स्वेट-सीबम इमल्शन (BZ118)

- आर्टिफिशियल एक्क्राइन स्वेट-सीबम इमल्शन, रेफ्रिजेरेटेड (BZ130)

- कृत्रिम पसीना - कस्टम पीएच, स्थिर नहीं ANSI-BHMA A156.18 (BZ142)

- कृत्रिम पसीना - स्थिर नहीं, ANSI-BHMA-A156.18 (BZ141)

- कृत्रिम पसीना DN 53160-2-BS EN 1811 (BZ125)

- कृत्रिम पसीना, AATCC परीक्षण विधि 15 पसीना - कस्टम पीएच, स्थिर नहीं (BZ138)

- कृत्रिम पसीना, AATCC परीक्षण विधि 15 पसीना - कस्टम पीएच, स्थिर (BZ139)

- कृत्रिम पसीना, AATCC टेस्ट विधि 15 पसीना - स्थिर नहीं (BZ135)

- कृत्रिम पसीना, AATCC TM 15 पसीना - स्थिर (BZ140)

- कृत्रिम पसीना, AATCC TM15 पसीना पीएच 4.3 स्थिर (BZ136)

- कृत्रिम पसीना, AATCC TM15 पसीना पीएच 4.3 स्थिर (BZ137)

- कृत्रिम पसीना, AATCC TM15 पसीना पीएच 4.3 स्थिर (BZ148)

- कृत्रिम पसीना, क्षारीय, कस्टम पीएच। 200 मिली (BZ156)

- कृत्रिम पसीना, कस्टम पीएच - स्थिर। (BZ129)

- कृत्रिम पसीना, GMW 14334, क्षारीय, गैर-स्थिर (BZ128)

- कृत्रिम पसीना, ISO 105-B07 अम्लीय समाधान - स्थिर नहीं (BZ151)

- कृत्रिम पसीना, ISO 105-B07 एसिडिक सॉल्यूशन - पीएच 5.5, स्थिर (BZ154)

- कृत्रिम पसीना, ISO 105-B07 एसिडिक, कस्टम पीएच (BZ155)

- कृत्रिम पसीना, ISO 105-B07 क्षारीय समाधान - स्थिर नहीं (BZ152)

- कृत्रिम पसीना, ISO 105-B07 क्षारीय समाधान - पीएच 8.0, स्थिर (BZ153)

- कृत्रिम पसीना, ISO 105-B07 क्षारीय, कस्टम पीएच, स्थिर (BZ158)

- कृत्रिम पसीना, आईएसओ 11641 पसीना - कस्टम पीएच, स्थिर नहीं (BZ145)

- कृत्रिम पसीना, ISO 11641 पसीना - कस्टम पीएच, स्थिर। 200ml (BZ146)

- कृत्रिम पसीना, ISO 11641 पसीना - स्थिर नहीं। 200ml (BZ143)

- कृत्रिम पसीना, आईएसओ 11641 पसीना - स्थिर (BZ144)

- कृत्रिम पसीना, आईएसओ 12870 पसीना - कस्टम पीएच, स्थिर नहीं (BZ149)

- कृत्रिम पसीना, आईएसओ 12870 पसीना - कस्टम पीएच, स्थिर (BZ150)

- कृत्रिम पसीना, ISO 12870 पसीना - स्थिर नहीं (BZ147)

- कृत्रिम पसीना, ISO 3160 - स्थिर नहीं। 200ml (BZ123)

- कृत्रिम पसीना, आईएसओ 3160 - स्थिर। (BZ127)

- कृत्रिम पसीना, आईएसओ 3160 - स्थिर। 200ml (BZ124)

- बीएस एन 1811-2011, कृत्रिम पसीना कस्टम पीएच (BZ121)

- बीएस एन 1811-2011, कृत्रिम पसीना स्थिर (BZ120)

- बीएस एन 1811-2011, कृत्रिम पसीना, कस्टम पीएच, स्थिर (BZ122)

- D4265-14 कृत्रिम सीबम - स्थिर नहीं (BZ116)

- D4265-14 कृत्रिम सीबम - स्थिर (BZ117)

- DIN 53160-2-2010-10 कृत्रिम पसीना - कस्टम पीएच, स्थिर नहीं। 200ml (BZ133)

- DIN 53160-2-2010-10 कृत्रिम पसीना - कस्टम पीएच, स्थिर। 200ml (BZ134)

- DIN 53160-2-2010-10 कृत्रिम पसीना - स्थिर नहीं 200ml (BZ131)

- DIN 53160-2-2010-10 कृत्रिम पसीना - स्थिर 200ml (BZ132)

- DN 53160-2-BS EN 1811, कृत्रिम पसीना (BZ119)

- GMW14334 पसीना, अम्लीय गैर-स्थिर (BZ159)

- कृत्रिम लार

- कृत्रिम मूत्र

- यूरोलॉजिकल इम्प्लांट्स के संक्षारण परीक्षण के लिए कृत्रिम मूत्र, गैर स्थिर (BZ101)

- मूत्र संबंधी रोगजनकों को उगाने के लिए कृत्रिम मूत्र माध्यम (BZ103)

- कृत्रिम मूत्र स्थिर (BZ104)

- कृत्रिम मूत्र, सिंथेटिक मूत्र, नकली मूत्र (BZ186)

- DIN EN 1616-1999 कृत्रिम मूत्र (BZ102)

- DIN EN 1616-1999 कृत्रिम मूत्र (BZ102S), स्थिर

- यूरोलॉजिकल इम्प्लांट्स के संक्षारण परीक्षण के लिए नकली मूत्र, स्थिर (BZ188)

- अन्य नकली द्रव

- कृत्रिम एम्नियोटिक द्रव BZ259

- कृत्रिम जलीय हास्य द्रव (BZ276)

- कृत्रिम अस्थि मज्जा द्रव (BZ268)

- आर्टिफिशियल ब्रेन फ्लुइड (BZ256)

- कृत्रिम स्तन का दूध (BZ255)

- आर्टिफिशियल ब्रोन्कोएल्वोलर लैवेज (BAL) फ्लुइड (BZ305)

- कृत्रिम कैनाइन लार (BZ297)

- आर्टिफिशियल सेरेब्रोस्पाइनल सॉल्यूशन (ACSF, स्टेराइल) (BZ178)

- आर्टिफिशियल सेरुमेन (स्थिर नहीं) या सिंथेटिक ईयरवैक्स (BZ171)

- कृत्रिम सेरुमेन (स्थिर) या सिंथेटिक ईयरवैक्स 50g (BZ172)

- कृत्रिम कोलेस्ट्रॉल द्रव (BZ265)

- कृत्रिम कॉलोनिक द्रव (बाँझ) pH7.8 (BZ177)

- कृत्रिम कोलोस्ट्रम द्रव (BZ306)

- आर्टिफिशियल डैंड्रफ या सिंथेटिक डैंड्रफ (BZ293)

- आर्टिफिशियल एंडोसोमल बॉडी फ्लुइड (BZ260)

- कृत्रिम बिल्ली की लार या बिल्ली की लार (BZ301)

- कृत्रिम गैस्ट्रिक द्रव (बाँझ) Ph1.5 सिम्युलेटेड गैस्ट्रिक द्रव (SGF) -स्टेराइल (BZ175)

- कृत्रिम आंत्र द्रव (स्टेराइल) pH6.8 सिम्युलेटेड आंत्र द्रव (SIF) -स्टेराइल (BZ176)

- आर्टिफिशियल ल्यूमिनल फ्लुइड (BZ283)

- कृत्रिम लसीका द्रव (BZ267)

- कृत्रिम लाइसोसोमल द्रव (BZ257)

- कृत्रिम मासिक द्रव (BZ266)

- आर्टिफिशियल म्यूकस मैट्रिक्स (BZ275)

- कृत्रिम नाक द्रव (BZ251)

- कृत्रिम नाक बलगम (BZ253)

- कृत्रिम नासोफेरींजल द्रव (BZ252)

- आर्टिफिशियल ओटिटिस मीडिया फ्लुइड (BZ304)

- आर्टिफिशियल पेरिफेरल लिम्फ फ्लुइड (BZ303)

- कृत्रिम कफ (BZ296)

- कृत्रिम प्लाज्मा द्रव (BZ273)

- कृत्रिम फुफ्फुस द्रव BZ258

- आर्टिफिशियल रीनल ट्यूबलर फ्लुइड (BZ269)

- कृत्रिम राइनोरिया (BZ295)

- आर्टिफिशियल सीरम अल्ट्राफिल्ट्रेट (BZ307)

- कृत्रिम थूक मैट्रिक्स (BZ274)

- कृत्रिम उल्टी द्रव (BZ282)

- आर्टिफिशियल वाउंड फ्लुइड एक्सयूडेट (BZ292)

- गैंबल सॉल्यूशन लंग फ्लुइड (BZ284)

- हांक का संतुलित नमक समाधान (BZ261)

- संशोधित-सिम्युलेटेड बॉडी फ्लुइड (स्टेराइल) (BZ174)

- फागोलिसोसोमल सिमुलेंट फ्लुइड (PSF) (BZ262)

- SBF सिम्युलेटेड बॉडी फ्लुइड (स्टेराइल) सिम्युलेटेड बॉडी फ्लुइड (BZ173)

- सिम्युलेटेड बेबी हैंड्स स्वेट (BZ298)

- नकली पित्त रस (BZ263)

- सिम्युलेटेड ब्लड मैट्रिक्स (BZ281)

- सिम्युलेटेड ब्लड सीरम (BZ278)

- सिम्युलेटेड कॉक्लियर फ्लुइड (BZ286)

- सिम्युलेटेड डुओडेनल फ्लुइड (BZ299)

- सिम्युलेटेड एंडोलिम्फ फ्लुइड (BZ287)

- सिम्युलेटेड एक्स्ट्रासेल्युलर फ्लुइड (BZ280)

- नकली हेपेटिक द्रव (BZ264)

- सिम्युलेटेड इंफ्लेमेटरी फ्लुइड (SIF) (BZ302)

- सिम्युलेटेड इंटरस्टीशियल फ्लुइड (BZ254)

- सिम्युलेटेड इंटरस्टीशियल लंग फ्लुइड (SILF) (BZ300)

- सिम्युलेटेड इंट्राप्लुरल फ्लुइड (BZ290)

- सिम्युलेटेड लंग फ्लुइड (BZ179)

- नकली अग्नाशय रस (BZ271)

- सिम्युलेटेड पेरिकार्डियल फ्लुइड (BZ288)

- सिम्युलेटेड पेरिल्मफ फ्लुइड (BZ285)

- सिम्युलेटेड पेरिटोनियल फ्लुइड (BZ289)

- नकली प्रोस्टेट द्रव (BZ272)

- सिम्युलेटेड रीनल फ्लुइड (BZ270)

- नकली वीर्य समाधान या सेमिनल तरल पदार्थ (BZ180)

- सिम्युलेटेड सीरस फ्लुइड (BZ291)

- नकली श्लेष द्रव (BZ183)

- नकली आँसू (BZ182)

- सिम्युलेटेड ट्रांससेल्युलर फ्लुइड (BZ279)

- नकली योनि द्रव (SVF) (BZ181)

- सिम्युलेटेड विट्रियस ह्यूमर (BZ277)

- सिंथेटिक फेकल स्टूल (BZ308)

- सिंथेटिक वर्निक्स केसोसा (BZ294)

- स्क्वायर मेश टेम सपोर्ट ग्रिड

- उन्नत नैनो सामग्री

- संपर्क करें

Polyetheretherketone (PEEK)

450 आईएनआर/Bottle

उत्पाद विवरण:

- अपवर्तक दर 1.658

- पवित्रता >99%

- आणविक भार ~288 g/mol (repeating unit)

- मेल्टिंग पॉइंट 343°C

- पीएच लेवल Neutral

- विषैला Yes

- गंध

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Polyetheretherketone

- PEEK

- Insoluble in water, soluble in concentrated sulfuric acid

- ग्राम प्रति घन सेंटीमीटर (g/cm3)

- ASTM D6262, ISO 1043

- [C6H4-OC6H4-CO-C6H4-O]n

- Decomposes before boiling

- (C19H12O3)n

- 1.658

- >99%

- Semi-crystalline, thermoplastic polymer

- ~288 g/mol (repeating unit)

- 29658-26-2

- 343°C

- 244-359-3

- Neutral

- Yes

- Engineering plastics, high-performance components, electrical insulation, medical implants

- 39079990

- Polyetheretherketone (PEEK)

उत्पाद वर्णन

Polyetheretherketone (PEEK) Properties /Description

Polyetheretherketone (PEEK) is generally immediately available in most volumes. Nanochemazone produces to many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information is available as is a Reference Calculator for converting relevant units of measurement.

Exceptional Mechanical and Thermal Properties

With tensile strength ranging from 90 to 100 MPa and a thermal conductivity of 0.25 W/mK, PEEK withstands significant mechanical stress and elevated temperatures up to its 343C melting point. Its UL94 V-0 flammability rating and resistance to weather, chemicals, and impact ensure operational safety and material longevity across industries.

Versatile Applications Across Industries

PEEKs combination of chemical inertness, outstanding dielectric properties, and stability under harsh conditions supports its use in aerospace, automotive, medical, and marine engineering. It serves as a trusted engineering plastic for parts, electrical insulation, and medical implants, available in granules, powder, rods, sheets, and tubes to meet diverse application needs.

Reliable Safety and Storage

PEEK is non-poisonous, odorless, and tasteless, offering safety in handling and use. For best results, store it in a cool, dry place, away from direct sunlight. Its physiological inertness makes it suitable for food-contact and medical applications, while standard compliance (ASTM D6262, ISO 1043) assures quality and consistency.

FAQs of Polyetheretherketone (PEEK):

Q: How is Polyetheretherketone (PEEK) commonly processed for industrial applications?

A: PEEK can be processed using standard thermoplastic methods such as injection molding, extrusion, and compression molding. Its semi-crystalline nature and high melting point of 343C require precise temperature control during manufacturing, enabling the production of intricate, high-performance components for aerospace, automotive, and medical applications.Q: What benefits does PEEK offer compared to other engineering plastics?

A: PEEK stands out for its combination of high tensile strength, excellent impact resistance, thermal stability, and chemical inertness. Unlike many plastics, it retains mechanical properties at elevated temperatures and has a UL94 V-0 flammability rating, making it suitable for high-demand environments where safety and durability are paramount.Q: Where can PEEK be used and what forms are available?

A: PEEK finds applications in areas such as aerospace, automotive, electronics, medical devices, marine engineering, and chemical processing. It is supplied as granules, powder, rods, sheets, and tubes, enabling manufacturers and designers to select the most suitable form for their specific needs.Q: What are the usage and handling guidelines for PEEK products?

A: PEEK products should be stored in a cool, dry place away from direct sunlight to maintain material integrity. Handling is safe as PEEK is non-poisonous, odorless, and tasteless, but heat-resistant gloves are recommended when processing at high temperatures due to its elevated melting point.Q: When should engineers choose PEEK for demanding applications?

A: Engineers should select PEEK when they require a material that can withstand high mechanical stress, elevated temperatures, and aggressive chemicals while maintaining performance. Its superior weather resistance, low water absorption, and dielectric properties make it ideal for specialized and high-performance components.Q: Is PEEK suitable for medical and electrical applications?

A: Yes, PEEKs physiological inertness and biocompatibility make it approved for use in medical implants and instruments. Additionally, its excellent dielectric constant (3.2 at 1 MHz) and electrical insulation properties ensure reliable performance in electronic components.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email